Menu

80-84 (Shore A Durometer).

400 Volts/Mil at 60 cycles.

1000 hours (Atlas wet ray chamber ultraviolet).

200% min.

Polyvinyl chloride has a temperature crystallization temperature of 5° F (-15° C).

The PVC coating will burn if is exposed to continuous flame or heat above 400°F (204°C).

Extended exposure to temperatures exceeding 200 °F (93 °C) or to fire may cause the PVC coating to release potentially hazardous emissions affecting the health of individuals exposed to them.

Materials for electrical conduit with an outer PVC coating and inner yellow urethane, such as REPSA Yellow Coat®, have proven to be the optimal choice for most corrosive environments they may encounter, in comparison to other types of materials commonly used in electrical conduit systems.

With our REPSA® Production System (SPR®), we develop a coating that meets the specifications established in the NEMA RN1-2018 standard, achieving extraordinary adhesion that surpasses the most severe performance tests.

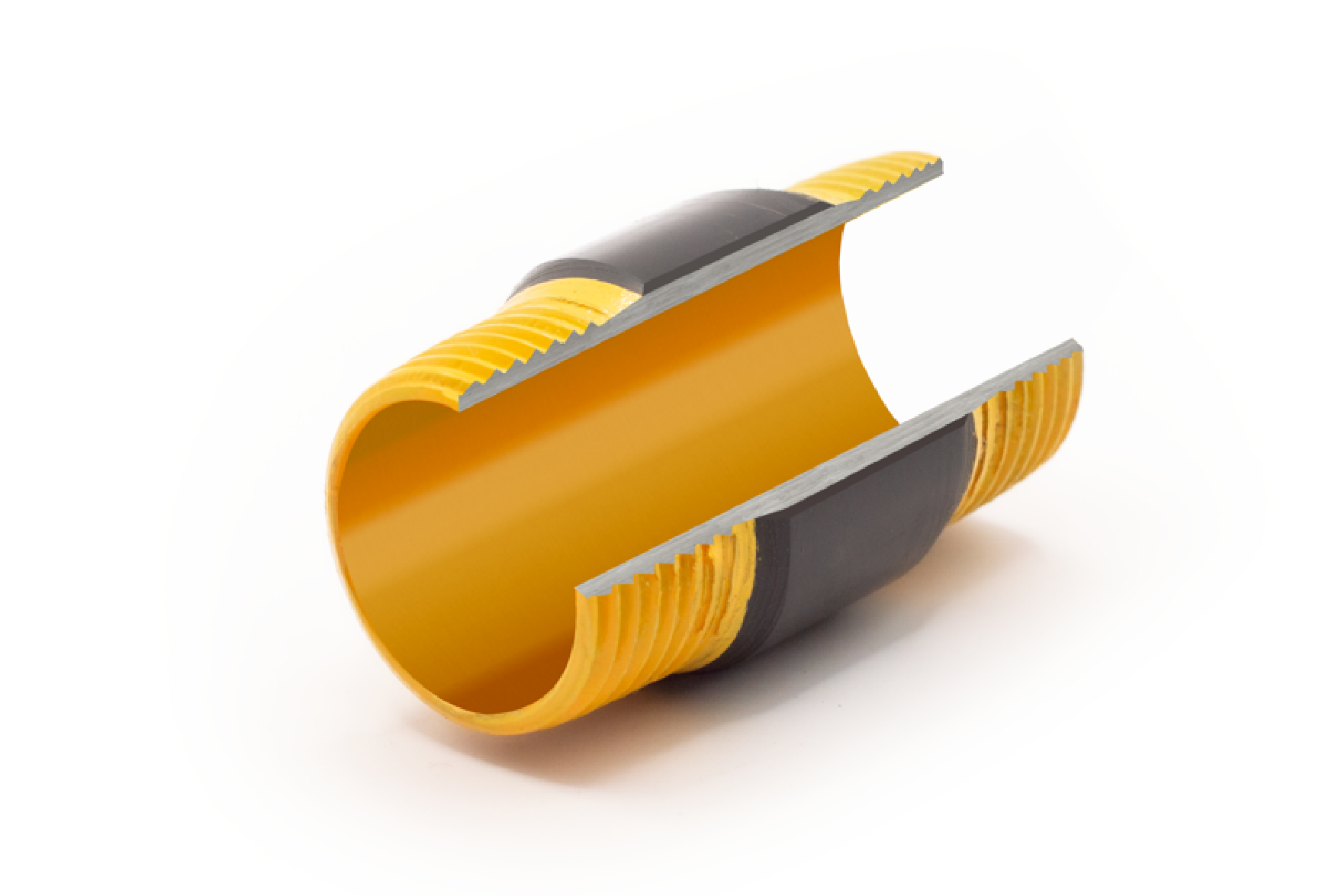

In addition to the outstanding exterior PVC coating of REPSA Yellow Coat®, the interior of the conduit and fittings is coated with flexible yellow urethane, providing the inner coating with increased resistance against damage or cracking during on-site conduit bending.

The threads of conduit pipes, elbows, and nipples, as well as the threads of couplings and other fittings, are coated with a layer of the same yellow urethane to protect the integrity of the piece while it is stored or handled during installation.

REPSA Yellow Coat® electrical conduit materials are the best option for the majority of corrosive environments to which they may be exposed.

We regularly update this section as new questions arise or changes to our services arise.

All REPSA YELLOW COAT products are sold solely and exclusively through our exclusive representative Materiales y Equipos del Sureste S.A. de C.V. Contact information can be found on their website: www.mes.com.mx

All REPSA YELLOW COAT brand base products are certified under the UL standard. The PVC coating is made under the parameters of the NEMA RN-1 standard which specifies the hardness of the plastic, its elasticity, the thickness that the plastic and the interior yellow urethane coating must have and the correct way to test the Adhesion of PVC and URETHANE to the metal substrate.

Yes. Recubrimientos Plásticos del Sureste has a production system certified under the international standard ISO 9001-2015, which assures its clients that the processes through which the product goes for its manufacturing are meticulously measured and verified to ensure the production of a product with international quality.

Yeah. All REPSA YELLOW COAT brand base products are UL certified.

Recubrimientos Plásticos del Sureste grants a quality certificate for the materials produced.

The authenticity of REPSA YELLOW COAT materials can be corroborated on the website sending an email with the invoice number to certificados@repsapvc.com

Subscribe to our newsletter to receive up-to-date news and articles about the company.

Over 28 years developing effective solutions to corrosion issues in industrial electrical conduit.

Este sitio web utiliza cookies para mejorar su experiencia. Asumiremos que está de acuerdo con esto, pero puede optar por no participar si lo desea. Leer más

Chatea con un asesor